FAQ

1).What is operation environment required?

Ambient temperature : -20°C to +40°C

Ambient humidity : 85 % or less (no condensation)

Explosion-proof construction : Not applicable to the work environment with explosive gases or explosive vapor

Environment to be avoided :

1. A place with organic solvent or volatile powder

2. A place with a plenty of powder and dust of general substances

3.A place with considerable amount of acids and salts

Shelter required: When installing hoist or winch outdoors or to the place where the hoist is exposed to direct rain, wind and snow, shelter the hoist under a roof to protect it from rain, wind and snow.

2).What kind of precautions should be paid at the time of operation of hoist or winch?

1.The operator of winch is required for qualifications according to applicable laws and ordinances.

2.Prior to starting of use, carry out the daily checking and use after confirming the safety of function.

3.Don’t use exceeding the rated rope tensile force.

4.The operator of winch must not be apart from the operating position under the loading condition.

5.In order to prevent the layer down due to over loosening of rope, irregular winding, etc., operate according to the suitable operating method.

6.Wire rope must remain by 5 winding on the drum.

3).What are the ratings among lifting, pulling and rolling

Pulling application: P = μ x W Rolling application: P =μ x W + θ x W

P: Wire rope tension W: Weight η: Sheave efficiency μ: Friction Factor θ: Gradient (degree°)

The pulling force is calculated from the mass of the load to be load multiplied by the surface friction factor and gradient resistance. The rolling resistance is around 0.15 for rubber wheels on the concrete surface and around 0.01 for a cart with steel wheels on the steel tracks.

Example of rolling forces

4).How to determining required horsepower?

One theoretical horsepower is equivalent to 33,000 lbs being lifted one foot in one minute. This equation does not account any of the inefficiencies inherent in motors, gearreductions, bearings or rigging.

Horsepower required > (Line pull (lb) x Line Speed)/33,000 ft-lb

5).What are speed load consideration

The line speed of a winch or hoist is based on how fast the rum is turning as it is winding line on or off the drum.

As a general guide, increasing the drum core diameter will increase line speed with a proportionately equal decrease in pull. The first layer of wire rope on the drum delivers the slowest speed and the maximum line pull, but a full drum delivers the maximum speed and minimum line pull.

6).Why is the importance of fleet angle

In order to promote proper spooling of the wire rope it is recommended a fleet angle 1 1/2° for

smooth drums and 2° for grooved drums to be maintained. Exceeding these recommendations may cause poor spooling from rope piling up, and possible damage to the wire rope through crushing and abrasion.

Experience shows the correct distance between the centers of winch drum and sheave for are the equivalents of approximately 19 times drum width in meter for 1 1/2° and 15 times drum width for 2° fleet angle

θ= 1.5° on smooth drum θ= 2.0° on grooved drum

Minimum distance(L) between the centers of winch drum and sheave When θ= 1.5° approximately 19 times drum width(W) in meter and when θ= 2.0° approximately 15 times drum width(W) in meter

7).Why is the D/d ratio so important?

Wire rope fatigue and irregular wear caused by using a smaller than recommended D/d ratio. For this reason “THAC” winch conform to EN 14492-1 standards which recommends a of 15:1 (D/d) ratio for lifting and lowering applications.

8).How do you calculate the D/d ration

The drum is generously dimensioned to obtain a minimum D/d ratio ( first layer pitch diameter/rope diameter)

9).Why is the wire rope safety factory so important?

Wire rope fatigue and irregular wear caused by using a unsuitable rope in construction, strength or having any defects. A rope safety factor of 5 times for lifting and lowering applications and a 3.5 times for any hauling of pulling applications

10). How do you calculate the rope safety factory?

Rope safety factory = Rope breaking strength (kg) / Winch or Hoist Rating For this reason “THAC” winch conform to EN 14492-1 standards which recommends a minimum of 5:1 wire rope safety factory for lifting and lowering applications.

11).Why is the important of freeboard?

Freeboard is the amount of space from the top layer of the wire rope to the outside of the drum flange.“THAC” follows EN 14492-1 which recommend a minimum of 1.5 times wire rope diameter of freeboard be maintained.

12).What is duty cycle?

The duty factor of the motor is a percentage of the total load operating time and the total load operating time plus the total resting time. Calculate the percentage duty cycle according to the follow formula. Duty Factor (%ED) = Tb/(Tb+Ts) x 100 (%)

Where,Tb: Total load operating time Ts: Total resting time Tb + Ts = Approximately 1 to 10 minutes should be set

13).What is the classification of hoist or winch?

Explanation to drive FEM 9,511 (DIN 15020, ISO 4301) for rope drives Calculated operating times according to FEM 9,755

|

Load Spectrum |

Average daily operating time (hours/day) |

|

|||||

|

Light |

t≦2 |

2<t≦4 |

4<t≦8 |

8<t≦16 |

16<t≦24 |

||

|

Medium |

t≦1 |

1<t≦2 |

2<t≦4 |

4<t≦8 |

8<t≦16 |

||

|

Heavy |

t≦0.5 |

0.5<t≦1 |

1<t≦2 |

2<t≦4 |

4<t≦8 |

||

|

Severe |

t≦0.25 |

0.25<t≦0.5 |

0.5<t≦1 |

1<t≦2 |

2<t≦4 |

||

|

Duty Factor |

25% ED |

30% ED |

40% ED |

50% ED |

60% ED |

||

|

Driven Group |

ISO |

M3 |

M4 |

M5 |

M6 |

M7 |

|

|

FEM |

1 Bm |

1 Am |

2 m |

3 m |

4 m |

||

|

Max. Start/hour |

150≦ |

180≦ |

240≦ |

300≦ |

300≦ |

||

Light:Predominantly low loads

Medium:Frequently full loaded, however continuously lightly loaded

Medium:Frequently full loaded, however continuously medium loaded

Extra-heavy:Regularly fully loaded

14).What are the different drum configurations?

In general, there are four dind of drum configurations for different lifting/lowering or hauling/pulling

applications

1. Winch with a plain drum

This is the most commonly used configuration. The rope is anchored at the drum and travels the barrel.

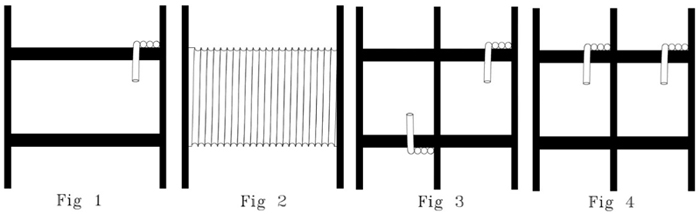

2. Winch with Extended drum (fig1)

The winch with extended drum to suit a wide variety of application

3. Winch with Grooved drum (fig 2)

Parallel grooving evenly distributes the load between and show to increases the life of the wire rope. Reduction of rope damage benefits the safety operation.

4. Winch with two ropes in opposite winding (fig 3)

It can be used as a traversing winch to move a carriage forwards and backwards in two direction on a level. The drum Is grooved for one rope, with a second rope fastening attachment on the drum.

5. Winch with several ropes (fig 4)

The winch is grooved for two or several ropes with additional wire rope fastening

attachment. Rope pays in and out together.

15). What is the explosion proof definition?

I、Class I - Locations: Are those in which flammable gases or vapors are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

Division

•Division I - Locations in which hazardous concentrations in the air exist continuously, intermittently, or periodically under normal operating conditions.

•Division II - Locations in which hazardous concentrations are handled, processed, or used but are normally within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown.

Group

•Group A - Atmospheres containing acetylene.

•Group B - Atmospheres containing hydrogen, or gases or vapors of equivalent hazard, such as manufactured gas. (not available in Division 1 design)

•Group C - Atmospheres containing ethyl-ether vapors, ethylene or cyclo propane.

•Group D - Atmospheres containing gasoline, hexane, naptha, benzine, butane, alcohol, acetone, benzol, lacquer solvent vapors, or natural gas.

II、Class II - Locations: Are those which are hazardous due to the presence of combustible dust.

Division

•Division I - Locations in which hazardous concentrations in the air exist continuously, intermittently, or periodically under normal operating conditions.

•Division II - Locations in which hazardous concentrations are handled, processed, or used but are normally within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown.

Group

•Group E - Atmospheres containing metal dust, including aluminum, magnesium and their commercial alloys and other metals of similarly hazardous characteristics.

•Group F - Atmospheres containing carbon black, coal or coke dust.